Rubber Molding

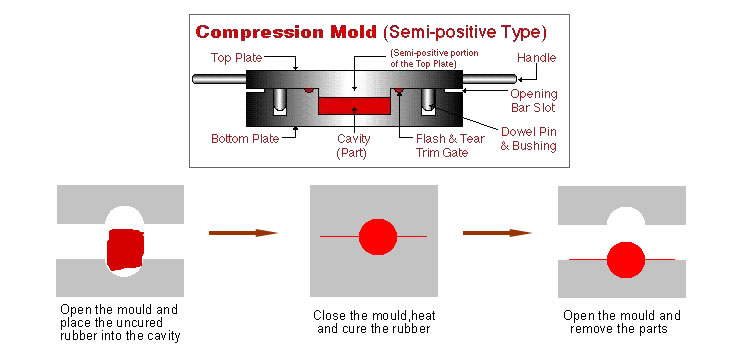

Compression molding is the oldest and simplest way to make rubber products. This method take longer to cure the rubber and each slug of rubber is often hand loaded into each cavity. However, due to the simplicity of the mold, it is the most economical mold to buy.

We have experiences in manufacturing rubber products for international customers. Most recently, we made windshield wipers in EPDM and Natural Rubber. We also made rubber window seals for a Tier 1 auto parts supplier in Canada.

Process: * First, open the mould and put. A precut or shaped "slug " of uncured rubber, at a set weight, is placed into the cavity. * Close the mould and place back into the press, then heat and cure the rubber. * After cooling, open the mould and remove the rubber parts. * The excess rubber, called flash, needs to be trimmed off the part. .

Pros:

* Lowest mold cost . * Making mould fast, about 8~10 days for simple shape part . * Little "throw away" material provides advantage on expensive compounds. * Often better for large parts . Cons: * Offers least product consistency.. * Difficult to control flash. Material: * NBR;EPDM;Silicon Rubber;FPM; Neoprene,etc |

Products & Equipment

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|